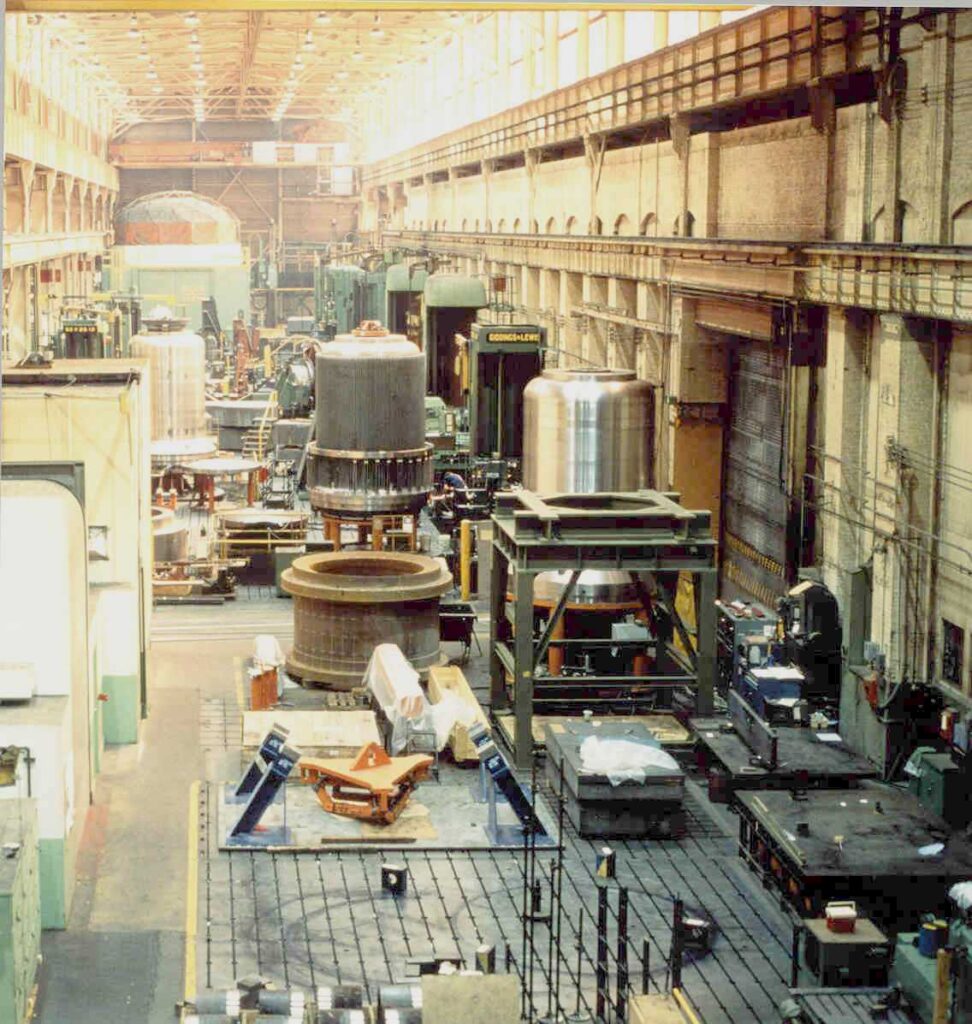

Precision Custom Component’s (PCC) Machining capabilities, developed over the past one hundred plus years, include CNC table/floor type horizontal boring mills, vertical boring mills, gantry mills, and CNC machining centers. PCC’s equipment list is extensive, supporting turn-key manufacturing.

PCC’s long-standing journeyman machinist apprenticeship program is approved by the Pennsylvania Department of Labor and Industry.

Large Machining

6 Vertical Boring Mills (VBM’s)

- Up to 20′ 4″ diameter swing

- Up to 18′ clearance under rail

- Contouring capability

- CNC 13′ swing dia. x 18′ under rail

5 Gantry Mills

- CNC Controls

- 5 sided machining

- 43′ x 16.4′ x 11.5′ machine envelope

13 Horizontal Boring Mills (HBM’s)

- CNC controls

- Up to 7″ spindle

- Up to 24′ 7″ horizontal and 14′ 7″ vertical travel

- 2, 3 and 4 axis contouring

- Rotary tables up to 150 Ton

Small Machining

- Vertical/horizontal machining centers

- Milling machines

- Lathes

- Drill presses

- Vertical N/C machining center

Support Facilities & Equipment

Custom, Special Purpose Machines (8)

- Boring, turning, facing, drilling machines

Tool Crib

- PCC employs a full time tool crib staff that is responsible for providing the standard, modified and/or custom made cutting tools to be used for a wide array of materials, finishes and tolerances. Extensive cutting tool data has been developed for tool life, efficiency and overall performance.

Bridge Cranes

- 150 Ton capacity, 50′ under the hook

Dimensional Inspection

- Coordinate Measuring Machine

- Laser and Optical Measuring Equipment, machine tools and gages

Calibration Program

- Machine tools and gages